What are Product Costs in Managerial Accounting?

These costs can be either fixed or variable depending on the type of product being manufactured. Fixed costs remain constant regardless of how much is produced, while variable costs vary based on production volume. The first step in activity-based costing is to identify all the different activities performed in an organization and then assign an overhead cost to each activity.

Discover more from Accounting Professor.org

Accurate comprehension of product costs is essential for informed business decisions. By understanding the components that contribute to these costs, businesses can refine pricing strategies, optimize resource allocation, and enhance profitability. Accurate cost allocation is essential for distributing indirect costs among products or services. Activity-Based Costing (ABC) is a widely used method that assigns overhead costs based on the activities driving them.

What is product cost and how to calculate (with example)

The price of the product may also be thought of as the price of the labor that is necessary to provide a service to a customer. Accounting standards like GAAP and IFRS require manufacturing overhead to be included in inventory costs, expensed as cost of goods sold when inventory is sold. This aligns with the accrual accounting principle, matching expenses with revenues. Gain insights into product costs to enhance business decision-making and improve pricing strategies through effective cost allocation.

What are some strategies for reducing direct labor costs?

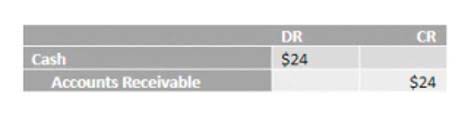

Tax codes, including IRC Section 263A, require capitalizing certain direct and indirect costs, impacting cash flow and tax liabilities. Usually, these product costs consist of costs include direct materials, direct labor, and production overheads. In some cases, they may also cover consumable production supplies, also known as direct expenses. For companies, these costs are crucial in determining the value of a product or service. It is essential to understand product cost to optimize direct materials usage. By understanding the product cost, a company can make informed decisions on reducing waste and increasing efficiency.

Role in Financial Reporting

- If the sale price is equal, it is a break-even situation, i.e., no profit or loss, and the sales price covers the cost per unit.

- Once you’ve arrived at an optimal budget for materials, add the labor cost to the total.

- Another way to reduce direct labor costs is to pay employees less per hour by either lowering wages or using cheaper labor sources.

- Let’s assume the company has $50 in manufacturing overhead costs for every widget produced.

- Upon completion, earn a prestigious certificate to bolster your resume and career prospects.

- Understanding product cost is essential for setting prices, managing budgets, and making strategic decisions.

Each of these components increases the product costs and plays a crucial role in it. Primarily, cost accounting covers the expenses incurred on developing or manufacturing a product. For service companies, these costs include the expenditure on the process of rendering services. So, allocating any portion of that cost to each product produced would be inaccurate. However, other indirect costs are more closely related to specific products or services. For example, the cost of setting up a production run for a particular product will likely be directly related to that product.

Understanding Product Costs for Better Business Decisions

Some companies may also allot them during the work-in-progress stage for products. Usually, companies avoid allocating factory overheads to units produced under the direct costing method. Usually, it includes skilled staff who complement the production process. On top of that, direct labor is the only component of product costs for service-based firms.

For example, if a carpenter makes the chair, the direct labor cost would include their wages and benefits. Product cost accounting is crucial for gaining insights into the profitability of a business. It helps you understand the financial implications of your decisions and accurately assess how much it costs to produce a given product. The cost of the product is reflected in the financial statements because it considers the manufacturing overhead expenses that are necessary according to GAAP and IFRS.

Why great narratives beat OKRs in early-stage products

In other words, direct materials are an essential part of the underlying product. Other materials that https://winslot999.org/ach-chargebacks-causes-ach-return-codes-how-to/ do not contribute directly to the production process fall under indirect materials. Overall, product costs cover all expenses incurred in producing a product. It does not cover any other items which do not contribute to those products. For service companies, these costs primarily include any expenses incurred on labor. Usually, these involve compensation paid to employees, such as salaries and wages.

Why Do Some Business Owners Overcost?

In most cases, the HOA Accounting price of a product should be set based on its cost, as well as market demand, competition, and other factors that affect the market price. Following these tips can avoid overcosting and undercosting in your own business. Setting the correct prices for your goods and services will make you more likely to attract customers and make money.

- Each of these components can vary significantly depending on the type of product and the manufacturing process.

- An average product cost per shirt of $103 is then determined by dividing the total annual product cost of $2.23 million by the annual production of shirts.

- By improving product quality, manufacturers can reduce material costs while reducing warranty expenses and increasing customer satisfaction.

- An assembly line worker putting together electronics or a carpenter crafting furniture are examples of direct labor.

- The distinction between product costs and period costs is essential for accurate financial reporting and internal decision-making.

- Usually, these expenses include salaries, wages, taxes, benefits, etc., paid to workers.

- To manage direct labor costs, businesses employ techniques like time-motion studies and labor efficiency metrics.

To eliminate overhead costs, a manager may modify product cost when making short-term product and unit pricing decisions. Manufacturing overhead includes all other manufacturing costs that are not direct materials or direct labor. These are indirect costs incurred within the factory environment that are necessary for production but cannot be easily or directly traced to individual products. Examples include rent for the factory building, utilities consumed in the production facility, and depreciation on manufacturing equipment. Indirect materials, such as lubricants for machinery or cleaning supplies for the factory floor, also fall under this category. Product costs are costs that are directly tied to the production of a specific product.